Firepump.AI

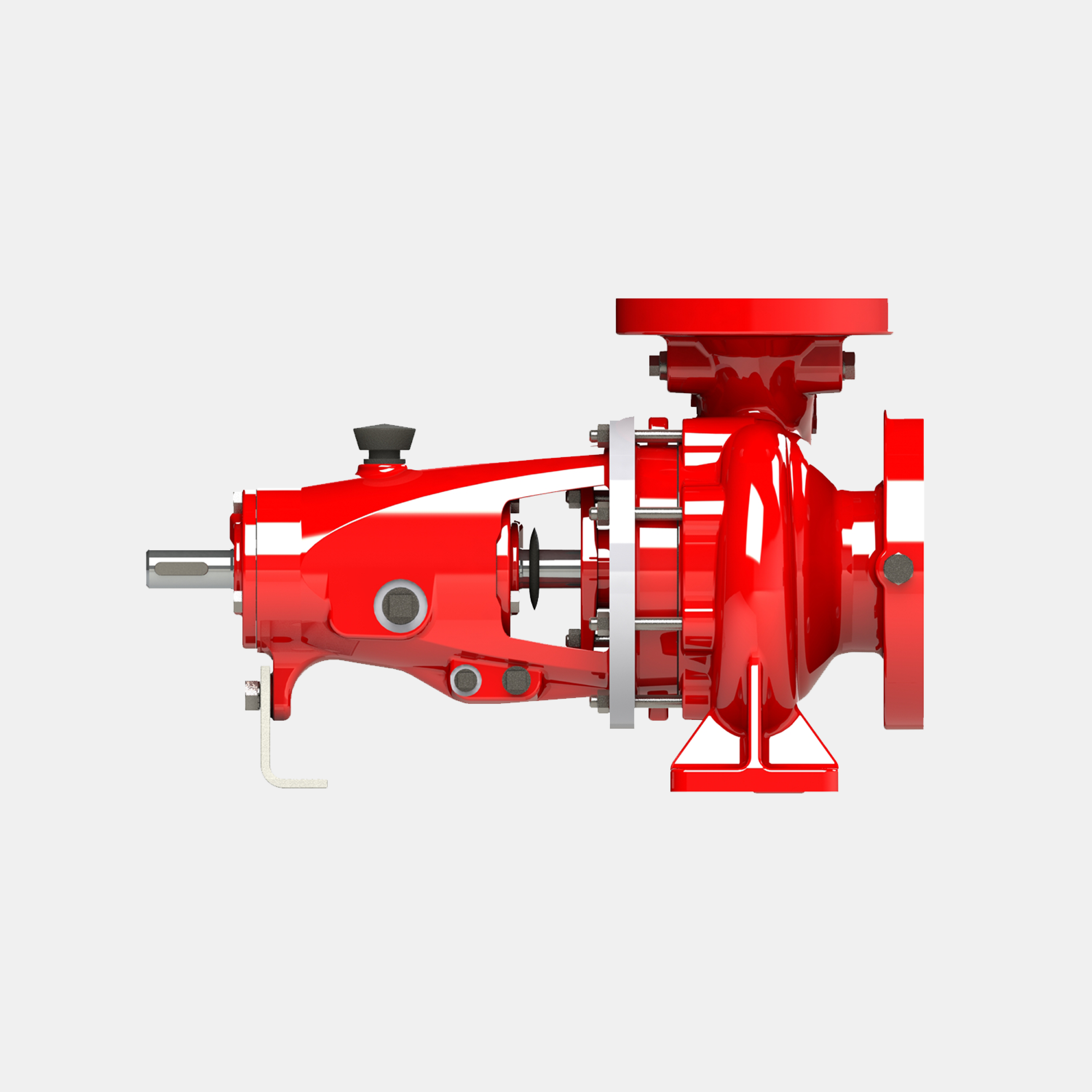

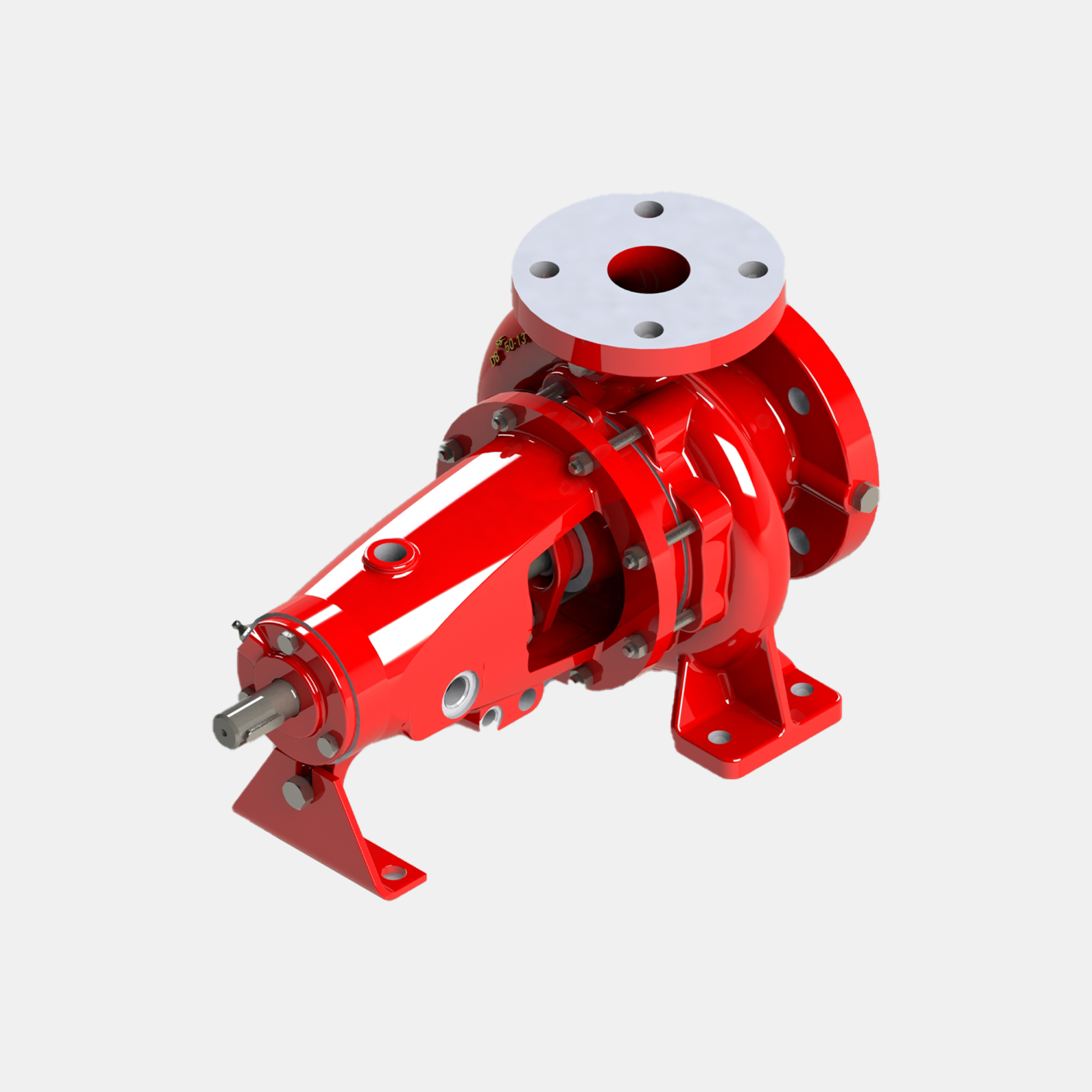

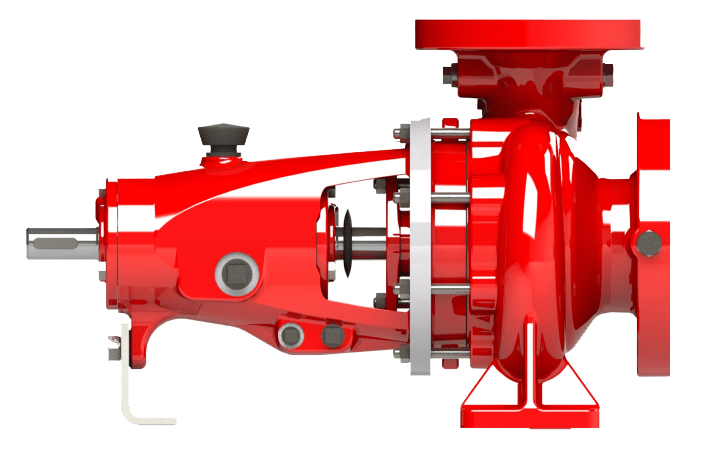

End Suction

With motor slide rails and a back pull out design, our end suction pumps offer easy access and maintenance. This space saving pump is one of the most commonly used arrangements

Approved, Reliable and Designed for Maximum Safety.

Choosing the right pump is more than just choosing a pump that can suit your building type – it’s about saving lives. That’s why we offer a wide range of pumps, each with specific use cases to ensure that safety is always at its highest. Our pumps have proven reliability, are all FM listed and UL approved, and have served as the highest quality, long lasting firepumps in the industry.

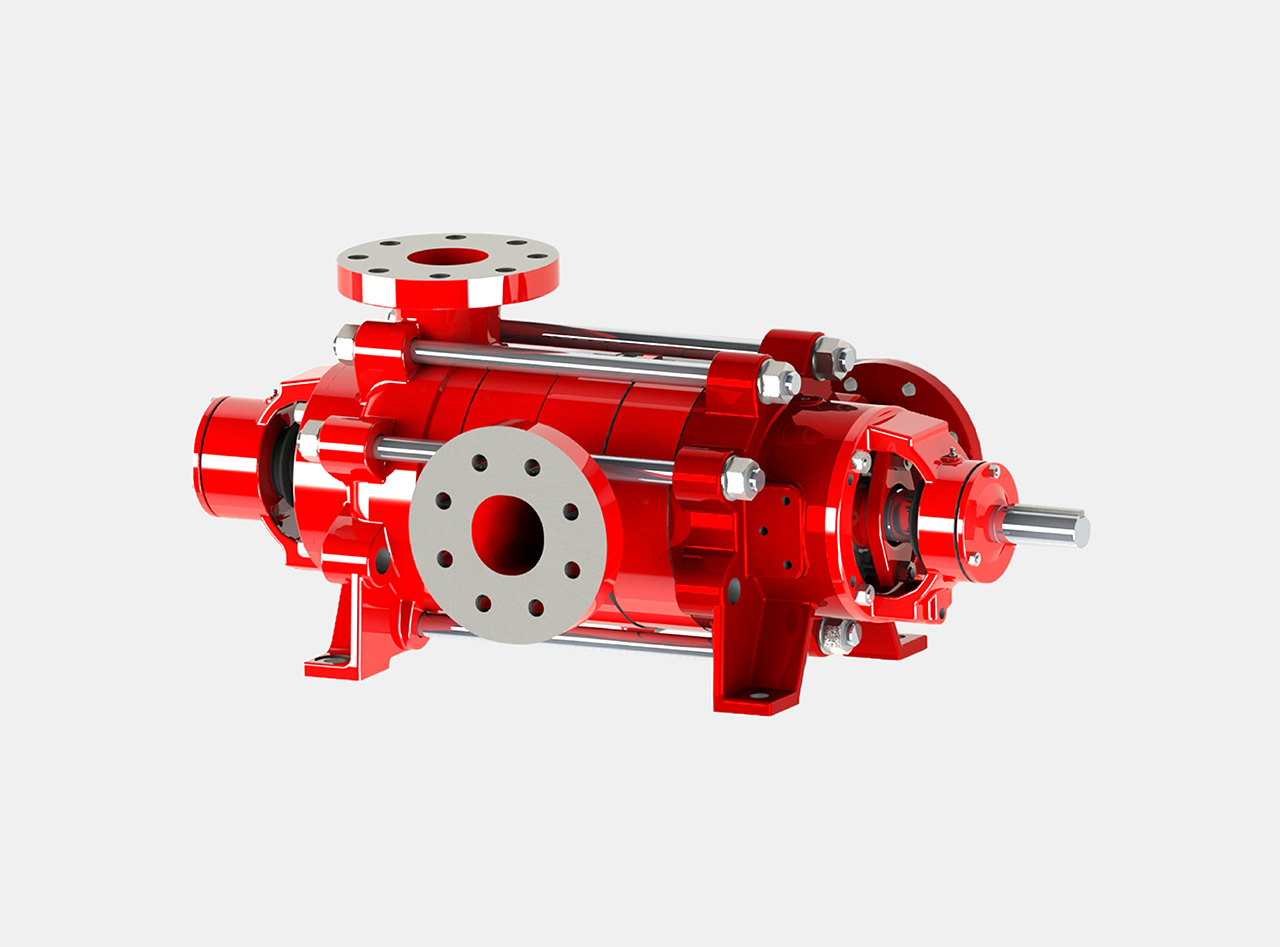

Configuration

- Model Name: FF series

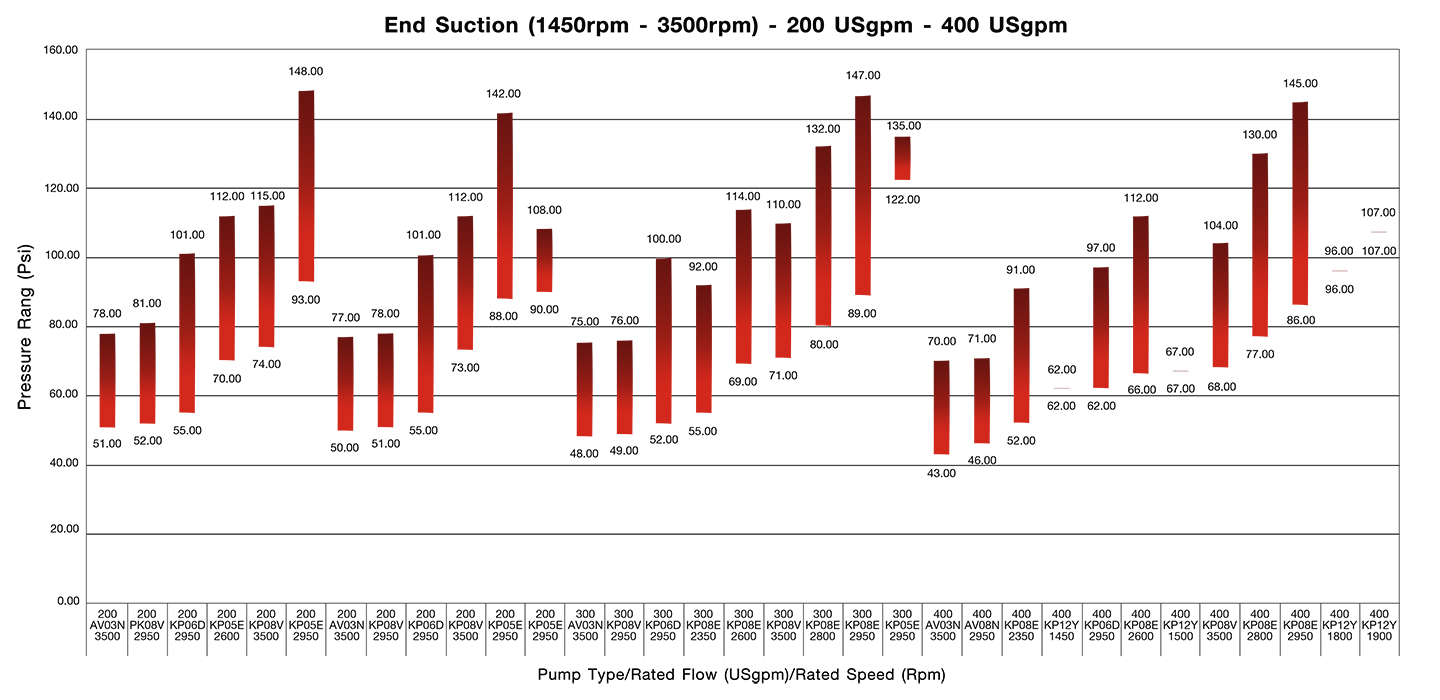

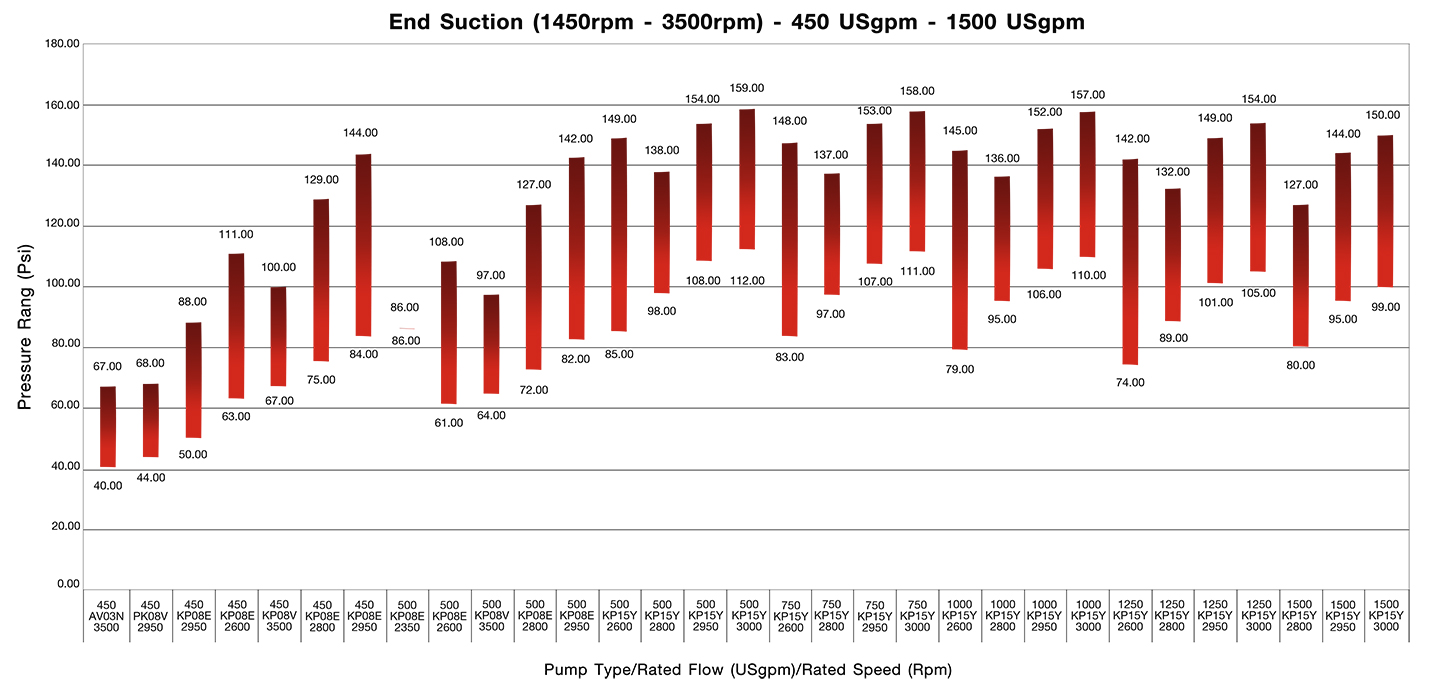

- Flow: 200 to 1500 US gpm

- Pressure: up to 159 psi

- Speed: 1480 to 3550 rpm

- Drive: Diesel and Electric

Features

- Motor slide rails and a back pull-out design

- Offer easy access and maintenance

- Using a horizontal shaft with an overhung impeller and bearing arrangement

- Operation ranges from 760 litres/min to 5,700 litres/min

Benefits

- Making this space saving pump one of the most commonly used arrangements.

- Suitable for use with both electric and diesel drives.

- Fluid is able to flow through the pump easier, requiring less suction pressure to feed the pump.

- Sprinkler systems

- Hydrant systems

- Monitor systems

- Water curtains

Warranty

We confirm that the fire equipment / parts are covered by a warranty period of 18 months from the date of dispatch or 12 months from the date of commissioning, whichever is the sooner.

Fire Pump Installation & Inspections

Depending on the type of fire pump you have, your pump may need to be inspected on a weekly, monthly or annual basis. It is important to keep in mind that fire pump inspections and testing are required by NFPA 25 and you should enlist the help of a fire protection professional to verify that your fire pump is performing at optimal levels. We can provide fire pump inspections and service for your facility.

Fire Pump Repairs

If you notice any issues or feel your fire pump needs to be repaired, you should contact us as soon as possible. It is important to get any issues with your system resolved so that the pump is ready to go in case of a fire.

Upgrade or Replacements for FM/UL Equipment

As OEM we can replace or upgrade existing fire pump systems without loosing the listings in line with the FM and or UL Guidelines. FM allowed pump manufacturer to do so. At the same time pump manufacturer is still responsible for the package and must make sure the controller and driver are sized correctly and are compatible with the pump and installation.What exactly does a fire pump do and why do I need one?

A fire pump increases the pressure coming from your water source to the rate that is required by your fire sprinkler system to respond in the event of a fire. Different pump sizes raise the pressure to different rates, so it should be sized appropriately when the system is first installed and when it is inspected every time there is a change to your building’s layout.

Do I need to worry about NPSH in fire pump applications?

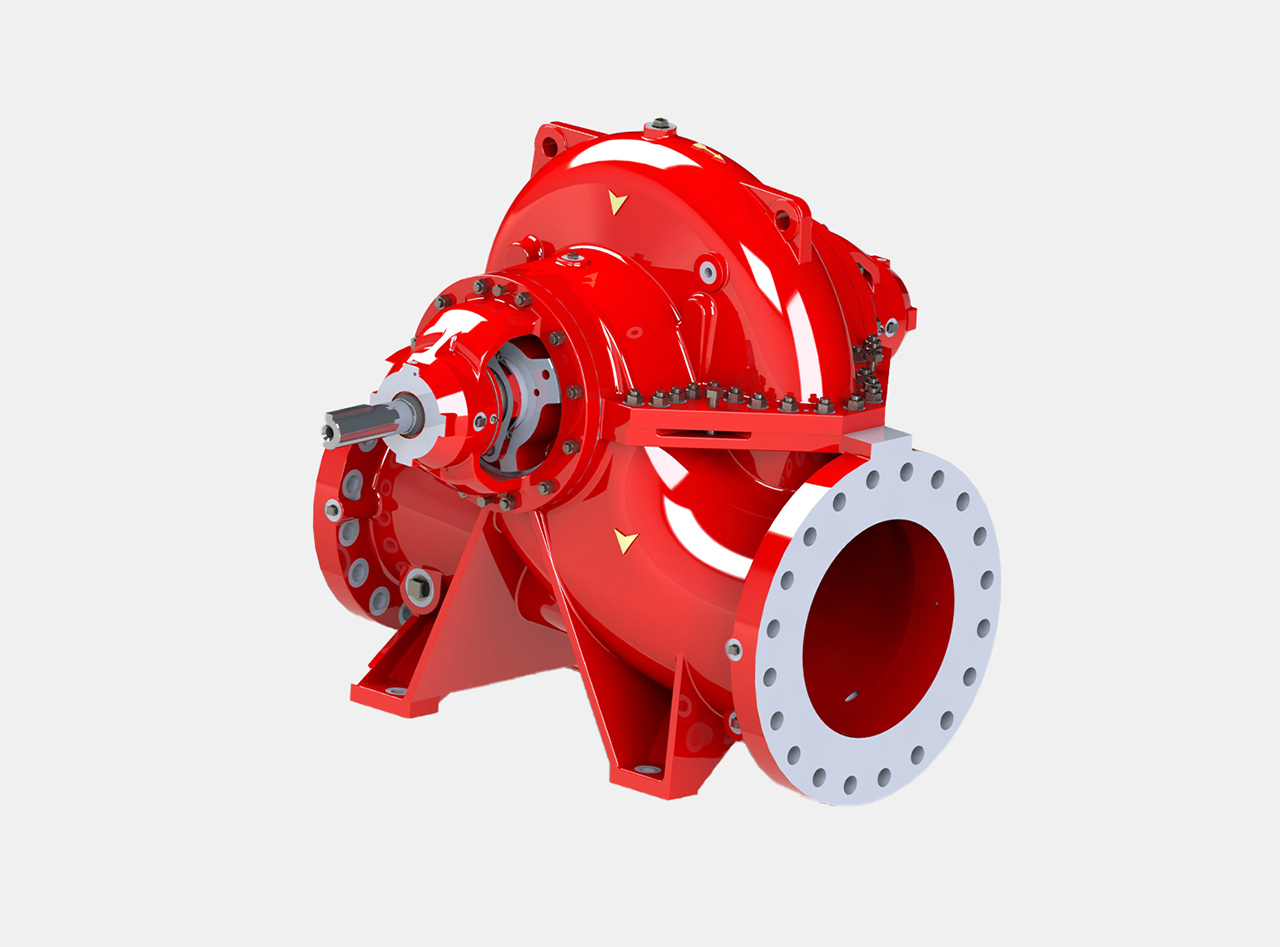

Rarely. NPSH (net positive suction head) is an important consideration in industrial applications, such as boiler feed or hot media pumps. With fire pumps, however, you are dealing with cold water, which uses all of atmospheric pressure to your advantage. Fire pumps need a “flooded suction,” where the water arrives at the pump impeller through gravity. You need this to guarantee a pump prime 100% of the time, so that when you have a fire, your pump operates. It is certainly possible to install a fire pump with a foot valve or some artificial means for priming, but there is no way to guarantee that the pump will function properly when called on to operate. In many split-case double suction pumps, it only takes approximately 3% of air in the pump casing to render the pump inoperable.

Is it recommended to use a Mech Seal with the main fire pump?

This is optional and can be supplied with a mech seal. Generally, the main fire pump is more reliable with a gland packing arrangement point of periodic maintenance.

Why does a diesel engine fire pump require two banks of battery?

A one bank battery is a high risk for a diesel engine fire pump as this equipment only starts during emergency requirements, therefore during an emergency if the sole battery fails to engage, there is no backup to start the pump.

Why do fire pumps need to be tested weekly for a 30 minute duration as per NFPA-20? And if it doesn’t, what are the consequences?

It is mandatory to do the weekly test of all main fire pumps for at least a 30 minute duration to ensure pumping systems are healthy. It also reduces the chances of any failures to start the pump in the case of an emergency.

Is it mandatory to inspect a fire pump’s performance every year with a certified contractor?

Yes, it is also mandatory to ensure pumps deliver the correct pressure and flow as per pump design to ensure the system is in compliance with regulatory standards

Is it mandatory that all recommended alarms should be compatible with the controller?

Alarms are mandatory in fire protection systems to ensure that all equipment is healthy at all times. This guarantees that all emergency equipment is working satisfactorily without any trouble.

What are the key checklist items I need to inspect for my pump?

Here we provide a comprehensive checklist to ensure the smooth running of your fire pump. Check the following and regulate if necessary:

- Pump is running smoothly, check for vibration and noise. Vibration should not exceed the limit as per given in HIS.

- Power consumption is within limit. Check the current, it should not exceed the value given on the nameplate of the motor.

- Ensure that there is no mechanical friction in the pump.

- Head developed by the pump is as specified on the nameplate of the pump.

- Check the temperatures of the pump and motor bearings.

- Temperatures of the thrust bearing should not exceed as per specs.